Pre Season Prep: A Story of Cuts and Bruises

Date: February 15, 2024

With the decision taken to do an engine swap after the first track day in 2022, 2023 was spent actually doing the engine swap. Fortunately there are a number of companies that sell off the shelf parts for these types of endeavours

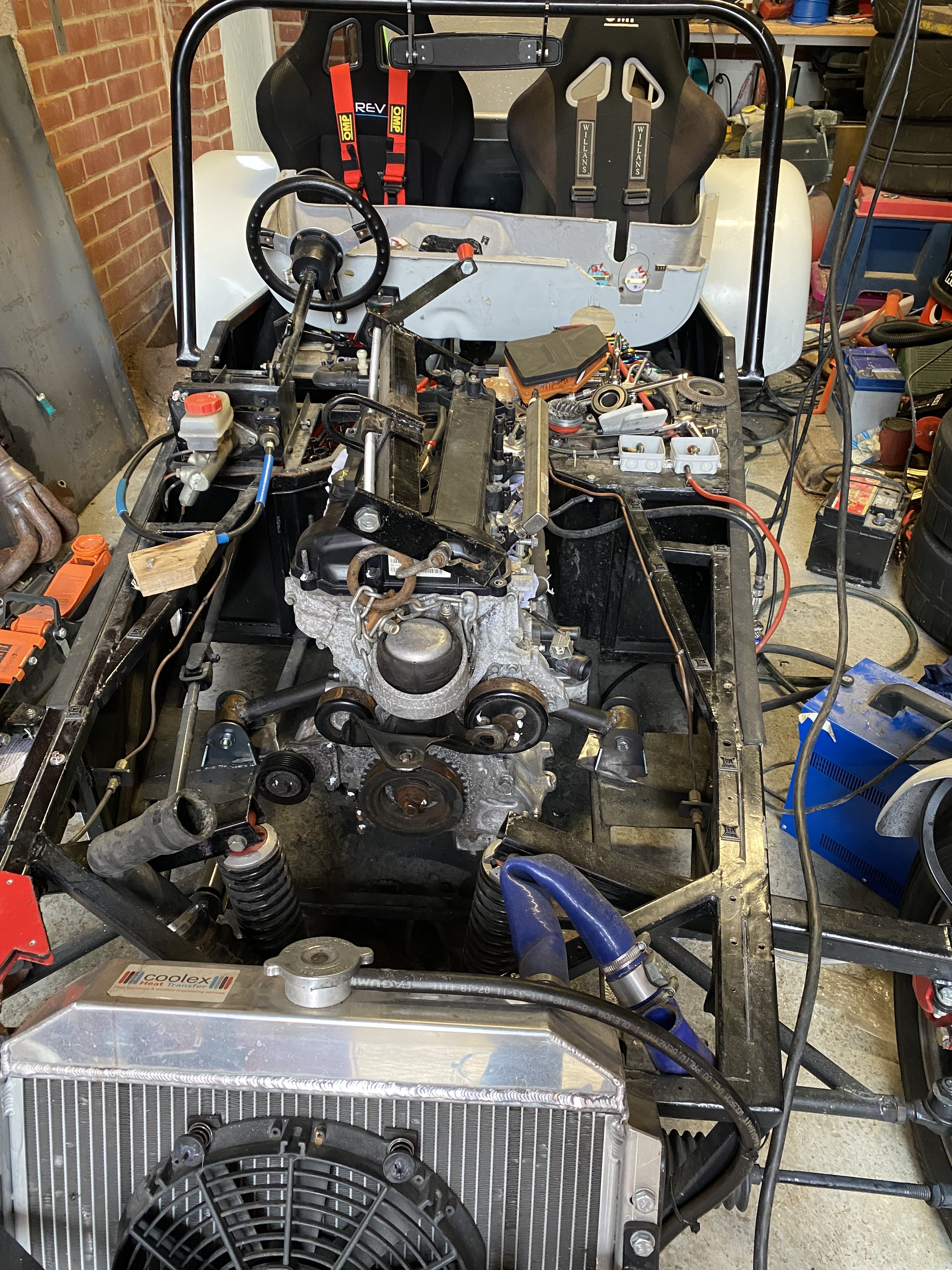

After sourcing a 2.0L Duratec engine from eBay and selling the original Pinto engine the initial checks were done to make sure it fitted even though the measurements had all been done previously it was still a nervous time checking fitment.

IT FITS!!

There was only one slight issue, the sump was now the lowest part of the car so something had to be done about that. Fortunately this problem had already been solved by other people as well. Another item to purchase and a low profile sump was delivered.

In kit form...

Off to the welders I went with what seemed like an A4 letter wrapped in cardboard! I can weld however not to the standards required for this sort of project. A few days later and a shiny new sump was assembled and ready to fit to the engine. Still the lowest part of the car but significantly higher and less likely to be clipped by a mis-calculated corner entry over the sausage kerbs!

You may be asking why I didn't just raise the engine so this wasn't a problem at all but I only had around 10mm of clearance between the highest point of the engine and the bonnet when it was closed and I really didn't fancy chopping holes in the fibreglass bonnet as my skills in that area are even worse than my welding skills as demonstrated by the picture of a previous soapbox kart I had built with a front nose for "better aero"...

With the engine now mounted in place (there were a lot more steps than just dumping it in but this is just a blog post not a full run down) it was a case of working out the exhaust, wiring, cooling and fueling for it.

Exhaust was sorted by another trip to the welders and he did a great job of joining the standard Duratec manifold to some custom pipework and then to the silencer which was another expense!

The fueling was already in place for a carburated engine but this was fuel injection so another run was required as well as a swirl tank and second fuel pump, a nice easy job once parts had been sourced from eBay and the local pipework company in Daventry.

Then it was a case of the brains for the engine...

After looking over many options I went with AT Power's offerings of their ITBs coupled with an ME221 ECU and a full plug in harness! It wasn't the cheapest option but it certainly made things easy! Bolt on the ITBs, find a place to mount the ECU, then just run all the wires to their respective positions, all pre terminated!

The ECU even came with a basemap which should have got the engine fired up first time.

This was too good to be true though and after checking the static timing it turns out the crank position was 180° out. A simple fix in the end but it took a while to diagnose.

With the engine installed the only thing left was EVERYTHING ELSE!

It turns out that turning a track toy into a fully compliant racing car involves quite a lot! The roll cage I had wasn't up to spec and was actually potentially dangerous! There was no fire extinguisher and that was just the start!

I wont bore you with the details but this took most of the year and when it came to the pre season test there were still some final things left to do but I basically had a racing car ready for a shakedown!

← Back to Blog